Maximizing Space With Vertical Storage Solutions

Managing a warehouse involves creating a system that maximizes floor space and improves workflow. This process simplifies inventory tracking, reduces waste and keeps operations running smoothly. Vertical storage solutions streamline operations by making better use of upright dimensions. Their flexibility allows businesses to store and retrieve materials with ease.

Learn more about efficient vertical storage solutions.

Types of Vertical Storage Solutions

Maximizing warehouse space requires solutions that improve accessibility, efficiency and coordination. Vertical storage solutions, like those offered by Summit Storage, are built with customization and durability in mind. This means businesses get long-lasting, space-saving storage systems designed for their workflow. Explore the following types of storage solutions.

Carousels

Carousels provide high-density storage by rotating materials into a convenient access position. This eliminates the need for workers to search through racks or manually move heavy items. This automation is invaluable for industries that handle bulky, delicate or high-volume inventory. Here are the types of carousels tailored for specific storage needs:

- Vertical garment carousels: These are designed for apparel manufacturing, warehouses, retail stores and textile industries. They allow businesses to store and retrieve hanging garments with minimal effort. By organizing clothing vertically, these systems prevent wrinkles, reduce handling time and improve inventory tracking.

- Print cylinder carousels: Print carousels are essential for printing and packaging facilities because they allow businesses to store and retrieve print cylinders in a secure position.

- Roll carousels: Roll carousels are perfect for industries that work with vinyl, fabric or paper. They keep roll materials organized and protected while being easily accessible. Automotive and upholstery manufacturing industries benefit from this system because it reduces waste and streamlines production workflows.

- Spool carousels: Businesses handling wire, cabling or tubing typically struggle with tangled or hard-to-access spools. A spool carousel keeps materials wound neatly and allows precise and controlled dispensing.

- Tire carousels: Designed for automotive manufacturers and tire distributors, these carousels stack tires while keeping them easily accessible and protected.

- Tray carousels: Tray carousels allow businesses to organize inventory in stacked trays to reduce wasted space and improve order fulfillment efficiency. Industries such as warehouses, manufacturing and pharmaceuticals use these systems to store components safely.

Custom Rack Solutions

Custom rack solutions offer a versatile alternative for businesses that require heavy-duty storage beyond standard shelving. Investing in custom racks ensures better load distribution and improved safety.

Rack systems include:

- Steel stackers: Steel stackers provide a framework for storing equipment, raw materials or finished products. Because they allow optimal stacking without compromising accessibility, they are a go-to option for warehouses, industrial manufacturers and distribution centers looking to maximize storage density.

- Stack racks: These modular racks are ideal for industries with fluctuating storage needs. Stack racks can be disassembled when not in use to free up floor space. Their adaptability makes them a cost-effective solution for logistics companies, seasonal warehouses, and businesses dealing with irregular inventory volume.

Sheet Metal Storage

Industries that work with sheet metal require storage solutions that prevent warping, scratching, or inaccessibility. Sheet metal storage systems make it easier to evenly distribute weight, secure stacking and quickly access materials. They are ideal for industries where specialized storage is required.

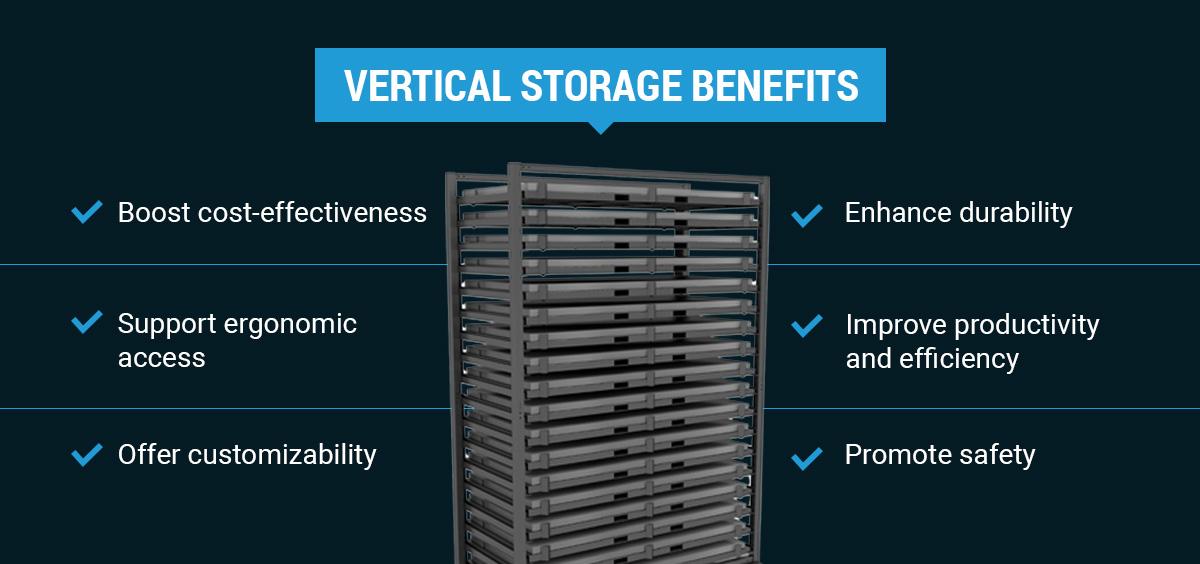

Vertical Storage Benefits

Vertical storage offers a significant advantage that impacts productivity and operational costs. Here are some perks companies can expect from these solutions:

- Boost cost-effectiveness: One of the most immediate benefits of vertical storage is its ability to increase available storage space without requiring additional square footage. Instead of expanding, businesses can make better use of unused vertical space within their current facility.

- Support ergonomic access: Traditional storage systems typically require workers to bend, reach or climb to access materials. This can lead to fatigue and injuries. Automated retrieval systems bring materials to the worker at an ergonomic height, reducing the need for physical strain.

- Offer customizability: Storage solutions can be designed to accommodate different sizes, weights, and workflow needs.

- Enhance durability: Vertical storage solutions can withstand daily use, heavy loads and harsh industrial environments. Many of these systems are constructed from high-quality steel and reinforced components, giving them the strength to support bulky materials and high stacking loads.

- Improve productivity and efficiency: The more time workers spend searching for items, retrieving materials or navigating cluttered aisles, the less time they have for production or order fulfillment. Automated industrial storage systems allow faster picking times, improved inventory accuracy and higher throughput.

- Promote safety: Overloaded shelving, unstable stacking and poor inventory management can lead to accidents, product damage and worker injuries. Vertical storage systems minimize these risks by creating structured environments. For example, roll-out racks allow workers to pull out required sheets without lifting entire stacks.

Warehouse Organization Strategies

Proper warehouse organization prevents delays, misplaced inventory, worker inefficiencies and safety risks, all of which directly impact productivity and costs. Below are best practices for space optimization in warehouses.

Assess Your Needs

Businesses must analyze their current warehouse setup before implementing or upgrading a storage system. They must consider the types of materials they store and whether they require specific solutions. They should also factor in how frequently they use these materials. Frequently used materials should be easily accessible, while slow-moving stock can be stored in higher or less prime space.

Plan a Layout

Once you’ve identified storage needs, design an efficient layout that supports workflow. An optimized warehouse should:

- Separate storage zones by function by assigning distinct areas for bulk storage, picking zones, shipping and receiving.

- Reduce travel time by placing frequently accessed inventory near workstations.

- Keep pathways clear for forklifts and workers to move around.

Train Your Employees

Investing in ongoing training allows employees to maximize storage solutions while maintaining a conducive working environment. Workers need to understand:

- How to operate vertical storage systems and carousels.

- Best practices for warehouse organization and item retrieval.

- Ergonomic handling techniques to prevent injuries when working with heavy materials.

Prioritize Maintenance and Improvement

A well-organized warehouse requires regular maintenance and inspections to prevent damaged racks and overfilled storage units. Companies like Summit Storage provide rack components to repair and reinforce broken systems. This allows businesses to extend the life span of heavy-duty racking structures.

Best upkeep practices include:

- Inspecting racks and storage systems regularly for signs of wear.

- Performing routine maintenance on carousels and automated systems to prevent breakdowns.

Warehouse arrangement should be an ongoing process. Regular evaluations help businesses adjust storage layouts, upgrade storage systems or integrate new technology.

Contact Summit Storage for Vertical Storage Solutions

Summit Storage specializes in vertical storage carousels and custom racking systems designed to accommodate various industry needs. Our products are durable and made in the U.S.

We work closely with you to understand your storage challenges and develop solutions that maximize space and improve efficiency and workplace safety. Our dedicated installation teams handle setup so you can start benefiting from your new setup.

Contact us today to learn more.